The latest EASA’s regulatory package on fuel policy updated in 2022 introduces different levels of performance-based variations, named fuel/energy schemes. It offers operators a range of frameworks to manage their fuel with greater flexibility at expenses of adopting new digital and analytical capabilities. These soft rules are set to favour digitalisation, but despite the growing interest in its implementation they have also resulted in a lack of definition of certain aspects that hinder the seamless adoption, integration, and management of the most advanced schemes, as well as the digital solutions on which they should be leveraged. EASA has already acted on providing guidance and support to the industry through the first draft version of the Fuel implementation manual from January 2024 currently under stakeholder consultation process.

The current processes in place and the challenges faced by the industry in implementing the fuel schemes have been the focus of our research in the context of the DATAPP project, to address the existing digital constraints and to propose solutions that push the adoption forward.

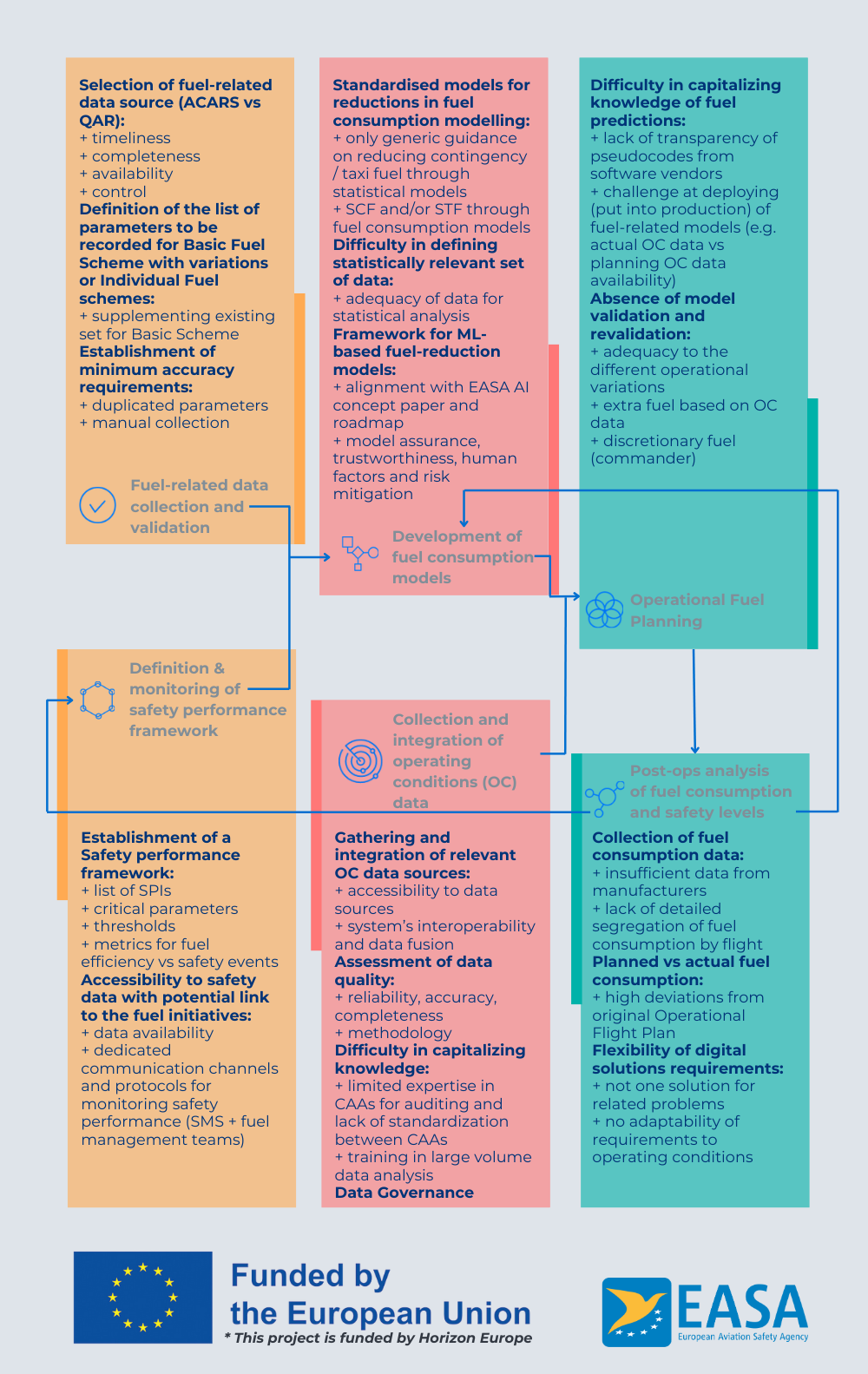

This blog describes the most recurrent challenges as well as potential solutions, focusing on the steps in the fuel management process where data plays a significant role. The process begins with the collection and processing of aircraft-specific fuel data, then operators integrate safety considerations into fuel policies and procedure to be able to develop fuel consumption models and integrate them into operational fuel planning. The latter also considers operations conditions data to be able to adapt the real needs. Upon flight completion, advanced analytics techniques are applied to the post-ops analysis of fuel consumption data to identify trends, patterns, and areas for fuel usage improvement.

Fuel related data

As the fuel management process begins with the collection and processing of aircraft-specific fuel data, the first challenge appears when operators need to decide which data source to use, as they need to navigate the existing trade-offs between sources, namely Aircraft Communication Addressing and Reporting System (ACARS) and Quick Access Recorder (QAR) that provides flight data. On one hand, ACARS only allows to collect a limited set of fuel parameters at specific points of the flight but in real-time. On the other hand, flight data offers a wider range of parameters with increased granularity, but with limitations in terms of availability and control of data. In front of this issue, it is proposed to develop guidance material or even applicable means of compliance (GM/AMC) for the minimum requirements and selection criteria of fuel-related data sources in terms of granularity of fuel-related data, availability and mechanisms for seamless collaboration between departments.

On top of the operators’ challenges related to the data sources, they encounter difficulties in defining the list of parameters to be recorded for the Basic Fuel Scheme with Variations or Individual Fuel Schemes. Operators and authorities are left with the responsibility of identifying additional parameters to supplement the existing set for the Basic scheme, ensuring they offer the necessary level of detail to support safe reductions. While this allows for more flexibility on the analytical approach to be followed, it also makes it more challenging for less mature analytical operators to launch the right enablers for activation of such analysis. As some operators are more advanced, sharing best practices for the definition of a comprehensive fuel data framework is recommended. The two key components of the framework should be a standardised list of fuel-related parameters to be recorded and scheme-specific data requirements, specifying the additional parameters necessary for the Basic Fuel Scheme with Variations or Individual Fuel Schemes.

While operators typically perform data quality assessments, they lack clear guidelines to establish minimum accuracy requirements for fuel parameters and to ensure data consistency. This is the case of duplicated parameters coming from different sources, namely ACARS and flight data, and the frequent cases of manual data collection that can introduce the errors in the process. The recommendation here lies on GM/AMC for data validation to define the minimum accuracy requirements, thresholds, methodologies for data consistency, how to assess the reliability of parameters and specific procedures for manual data collection, data entry, and quality control to minimise errors.

Development of fuel related data models

Fuel data collection, validation and analysis allow operators to develop and apply data analytics techniques on fuel consumption. It facilitates the creation of statistical or predictive models that provide insights into fuel usage for overall flights to plan fuel allocation more efficiently. The development of these models not only enable the identification of opportunities for reducing fuel amounts when deemed safe, but also help operators detect potential situations where fuel consumption trends deviate, and additional fuel needs to be added.

The stakeholder consultation showed that many operators already have statistical models developed and have been implementing them for a long time, but the amount of data and methods diverge widely among them due to the lack of detail in the current regulation. While EASA's guidance material provides some generic guidelines for reducing contingency or taxi fuels through statistical models, the fuel consumption modelling suffers from lack of standardised models for reductions and difficulty in defining the statistically relevant set of data.

The proposed solutions in the context of the development and implementation of fuel consumption models include mainly guidance material and best practice example from the community. A standardised framework for fuel consumption models could bring clarity on the methods to be applied and the specific methodologies for generalising statistical models. The current standards requiring a minimum of two years of operational data should be further developed to establish criteria for assessing the adequacy of data for statistical analysis providing recommendations on effective data sampling techniques.

Operational fuel planning

Fuel related data models are mostly statistical-based and thus, are usually deployed without going through validation or testing phases. However, as the industry matures in terms of the application of more advanced technical solutions (e.g. ML-based algorithms), it is clear that a framework is needed to ensure trustworthy and reliable algorithms, in particular those providing predictive capabilities for operational environments. This is the line captured in recent documents as the AI concept papers. Examples and best-practices should be shared for the steps of validation of the accuracy of the model and its reliability. Many operators are using providers’ digital tools for fuel reduction models in the planning phase. They face difficulties in accessing pseudocode and algorithm details, which limits their understanding of the underlying on the calculations performed by these tools. As a result, operators may also not be able to fully to validate the model's performance and have confidence in the fuel planning process. This generates mistrusts, pilots often compensating for this uncertainty by adding more discretionary fuel, undermining the efforts to achieve optimal fuel efficiency.

The transparency in algorithm details provided by software providers could be avoided through the provision of algorithms documentation and ensuring traceability of the indicators calculated. The access to the algorithm details would also support the authorities, facilitating the oversight with the transparency on the calculation process. As mentioned, the fuel consumption models have been implemented for a long time in some cases. However, these are usually deployed without going through validation or testing phases. This is acceptable as current models are statistical, but it will become crucial if models evolve to machine learning.

Definition and monitoring of safety performance framework

Despite improving flight efficiency and reducing environmental impact, fuel initiatives can be implemented only when ensuring the safety levels. The imperative activity here is the establishment of a safety performance framework that encompasses a series of strategic actions, defining a robust safety baseline for any proposed fuel scheme. There is a need for a detailed framework to define and implement Safety Performance Indicators for all fuel schemes, not only for the individual one. This should include a minimum list of SPIs, critical parameters, thresholds and clear differentiation between metrics for fuel efficiency and safety events. The definition of a standardised framework should be complemented by the reporting structure and process towards the authority. The detection of safety deviations is crucial to assess the stability of the fuel reductions and should be done in a proactive manner. These should be supported by the definition of precursor events, safety margins, monitoring of operating conditions and analysis of Annual Safety Reports consequential events. In terms of reporting, the frequency and format of the reporting towards authorities should also be addressed. As fuel initiatives imply changes to the daily operations, while maintaining safety levels, they require a close collaboration with safety department to ensure risks are identified in a timely manner. Safety data with potential link to the fuel initiatives should be accessible by both fuel and safety departments. Data availability should be complemented by communication channels and protocols for monitoring safety performance indicators related to fuel initiatives.

Collection and integration of operating conditions

A fundamental aspect of the flexibility provided by fuel schemes to gain and establish control over operational data and monitor is to ensure that safety levels are sufficient and remain constant. This data-driven approach involves the collection of operating conditions data, integration with other data layers like fuel-related data and safety indicators, and their use throughout the fuel planning process. The intrinsic limitations of the operational data collection and usage are similar to those of the fuel data. These include low reliability of data, lack of consistency along the data fuel management process and the governance of the data sources.

Standardised data formats and protocols are needed to ensure consistency and compatibility among operating data sources. This would include the recommended criteria to evaluate the reliability, accuracy, and completeness of the data collected and also a set of quality assessment methods that could be adopted by the operators. In addition, the access to the operating conditions data should be maintained at all stages of the process (planning, in-flight replanning and post-ops). Therefore, the relevant data should be synchronised and updated in real time for in-flight fuel planning and management. Looking at on ground processes, the manual monitoring of numerous data sources for multiple flights can be highly challenging and resource-intensive for dispatch personnel. The use of advanced technological solutions should be incentivised, such as automated monitoring tools and data analytics platforms. Even if the tools and systems may provide some data, but pilots may still encounter gaps in the availability of updated critical information, such as real-time weather updates, unexpected delays, or specific runway configurations. Therefore, communication protocols and channels should be established between dispatch and fuel management, but also between dispatch and flight crew. Another significant challenge encountered in the collection of operating conditions data is ensuring its consistency not only at different stages of the process but also across operations. The optimal solution for this issue would be a centralised platform that would consolidate information and provide the reference data to work with. This might be feasible, but with significant effort and limiting the market opportunities exiting today for data providers. What does seem feasible is a metadata centre where all available sources are defined together with the detailed description of what data they provide, how and when. Even if there would not be a unique owner of the data, it is ensured that everybody knows what is available and where.

Post-ops analysis of fuel consumption and safety levels

Finally, upon flight completion, advanced analytics techniques are applied to the post-ops analysis of fuel consumption data. Post-ops analysis involves comparing planned fuel consumption with actual fuel usage during flight operations. This analysis faces several challenges due to several factors, such as insufficient fuel consumption data, operational variability, lack of flexible digital solutions for different types of operations and limited pilot involvement in fuel performance assessment.

The Fuel Consumption Monitoring Systems (FCMS) together with the Flight Planning tool play a crucial role in evaluating fuel consumption in aviation operations. They need to be effectively integrated and used to ensure accurate post-ops analysis. From the regulatory perspective, additional provisions would allow for more flexibility regarding the requirements specified for FCMSs, in accordance with the operational nature of operators and the expected fuel initiatives.